This is the series of EXTRIPPER SYSTEM which RAISER MOON developed for removing paraffin-wax from 3D workpiece.

You use two special machines for EXTRIPPER SYSTEM.

This is EXTRA-S, which you use with EXTRIPPER JAM when you remove support material from workpieces.

This is EXTRA-US, which is used with EXTRIPPER BIKAN for removing residues of support material and finishing.

This is remover "EXTRIPPER JAM", which you use in EXTRA-S. It is solid at room temperature.

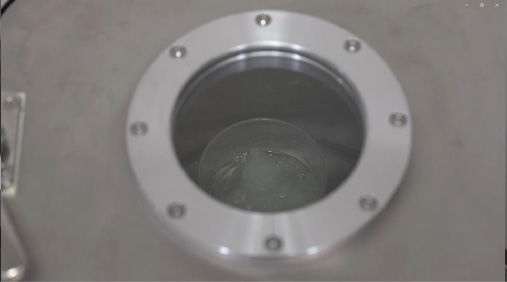

You should warm it up and make it liquid before putting your workpiece in there.

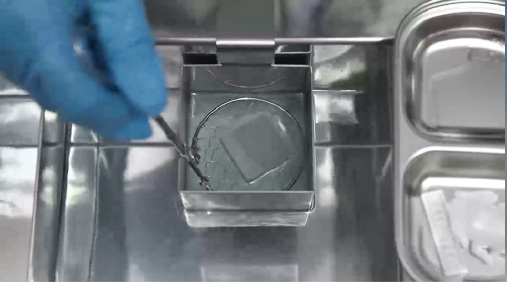

First, you open a lid and put a cup of solid JAM into EXTRA-S.

You put JAM into EXTRA-S, then set a temperature at 80 degrees and switch the machine on.

When JAM has changed into liquid, you're ready to remove support material.

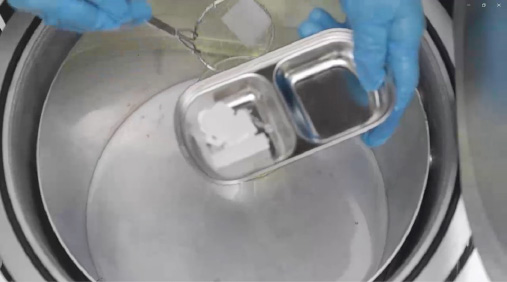

Fill a vessel fitting your workpiece with BIKAN.

This is EXTRIPPER BIKAN for finishing, which is also supposed to be warmed up.

Pour water into an ultrasonic cleaner.

Next, set a temperature at 60 ℃ and switch EXTRA-US on.

And set the vessel at the side of EXTRA-US like this way.

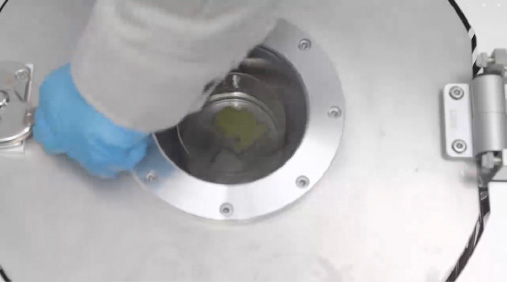

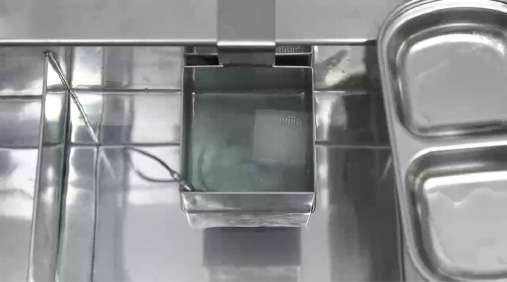

Put the workpieces into JAM which has been warmed at 80℃.

Then turn a vacuum pump on.

When it reaches 80 kPa, close the valve and switch the vacuum pump off.

You can see tiny bubbles come out of the workpieces and it means the removing process is in progress.

Gradually, support material comes off from the workpieces.

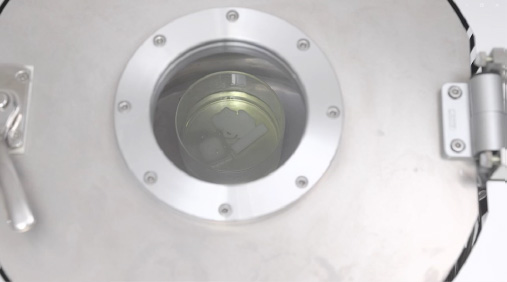

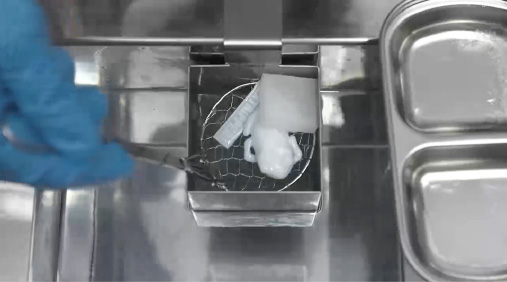

When support material has been removed, release the valve.

Take the workpieces out and move on to BIKAN process.

Support material has been removed and the workpieces are now covered with JAM.

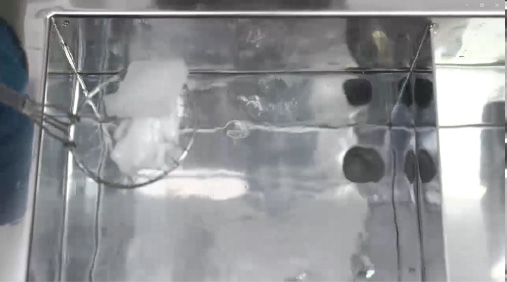

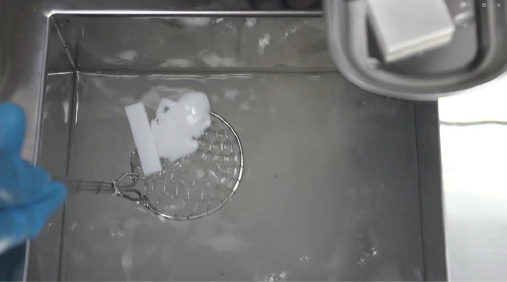

Next, you switch ultrasonic of EXTRA-US on.

Make sure that the temperature is set at 60℃.

Put the workpieces into BIKAN in EXTRA-US.

You can see residues come off from the workpieces.

Then you take the workpieces out from the tub and put it into hot-water tub.

You can finish your work by rinsing it in hot water.

In usual ways you had to spend a lot of time and effort removing support material, but this EXTRIPPER SYSTEM can make the process much faster and better.